As a retail business, the holiday season can be both a boon and a curse if you do not have the right strategies. It is one of the busiest seasons for business people, and with proper holiday inventory planning, you can proactively avoid any out of stock situations. You need to understand the issues clearly to meet the increased demand during the holiday season. adequately meet demand. Thus, without a proper inventory planning tool, there would be risks of going out of stock, resulting in lost sales.

What Is Out-of-Stock?

Out-of-stock is a situation when you cannot fulfill the demand for products. The average out-of-stock for retailers is almost 8%. This implies that when customers want to purchase an item, it is sold out most of the time. During the holiday season, everyone is often in a hurry to purchase items in demand, so the item goes out of stock. This leads to the customers’ disappointment, and they shift to other businesses. Businesses can lose loyal customers if stockouts occur often.

Reasons Leading to Stockouts

Stockouts can occur due to a variety of reasons. These are:

- Inaccurate inventory planning

- Erroneous inventory counts

- Lack of data, including previous sales, stock turnover, sell-through, etc., results in poor forecasting procedures.

- Incorrect safety stock calculations

- Ineffective reordering and restocking

- Inferior procedures for warehouse operations.

These are the reasons why stockouts occur. Most of them can be avoided with the help of a proper inventory planning tool.

How Can Out-of-Stock Circumstances be Avoided?

Let us see how out-of-stock situations can be prevented.

1. Avoid Stock Outs with Dynamic Safety Stock

Safety levels are assigned based on the demand variability and lead time of a product If you have inventory stored across multiple channels it is best to consider a buffer/ saftey stock for those products which are fast-selling with high demand variability.. Retail businesses need to maintain a high inventory turnover ratio and thus need to plan their safety stock more to avoid wastage. This procedure is excellent for preventing stockouts.

Most inventory planning systems offer this apprach to dynamic saftey stock that allows companies to optimize working capital by spending only on high-risk products, giving businesses more control over their supply chain.

2. Utilize Demand Forecasting

If you have products that are highly in demand across different channels, you should ensure that you place replenishment orders beforehand and receive the items before you run out of stock. You should also maintain an adequate safety stock to cover up for the time before the items are received. With accurate forecasts, you can estimate the reorder point, available stock, and present order quantities using previous sales data.

A reordering strategy can be essential to solving out-of-stock issues through reordering point warnings. This can be done with an inventory planning system which lets you know when inventory levels fall below a certain point. Businesses can control and replenish along three report types: reorder, replenish, and assembly. It can be used for demand forecasting, maximum/minimum order quantity, and reorder points.

3. Migrate to Automated Solutions

To maintain an accurate inventory, you should reduce human errors and replace manual processes with automated inventory planning. Spreadsheets are prone to errors. Businesses should start scanning for recording inventory, input information in the inventory planning system, and fulfill orders. Typing causes mistakes, but you can achieve accuracy with scanning.

The warehouse manager should consistently monitor the performance, measure performance and define maximum deficiency goals. The practice of constant monitoring allows you scope for improvement, identify deficiencies and take corrective measures. Many businesses offer incentives to employees when they exceed goals which increase productivity.

4. Quality Control

Inventory planning systems can automate the picking, packing, and shipping process through wave picking, zone picking, batch picking, and hyper picking. A productive picking process with quality control can ensure you are shipping the appropriate products to the right customers. It can eliminate returns, keep inventory quantities accurate, and help prevent stockouts.

5. Improved Supplier Relationship

Sometimes, stockouts occur due to reasons beyond your control. Suppliers might delay the delivery of goods, which would inevitably affect the inventory stocks. It is necessary to build essential relationships with all the suppliers and ensure better communication so that you can understand their challenges and keep the delay from affecting the stock levels. You should discuss any potential changes or problems. It would help if you also cleared your dues on time.

You should also provide enough lead time to your suppliers. Suppliers must deal with production problems, so it is advisable to set timetables and parameters straightaway. This way, the deliveries can be streamlined, and the goods will be received on time.

About the Company

Fountain9’s inventory planning system – Kronoscope with its dynamic demand sensing and inventory planning capability, allows companies to maintain flexibility in safety levels to manage cash flows and ensure business never run out of stock. The sophisticated AI engine, helps businesses by automatically creating dynamic purchase & replenishment plans, factoring in dynamic lead times, fill rates, shelf life, current inventory levels, open orders, and dynamic safety stock levels..

Additionally, Kronoscope helps businesses optimize their working capital and reduce the complexity of managing multiple inventories. It allows managers to identify the products likely to sell out and inventory levels in advance by accurately predicting stock-outs and suggesting appropriate safety threshold levels.With the softwares help, you can maintain an ideal inventory level to meet client demand, resulting in repeat business satisfactorily.

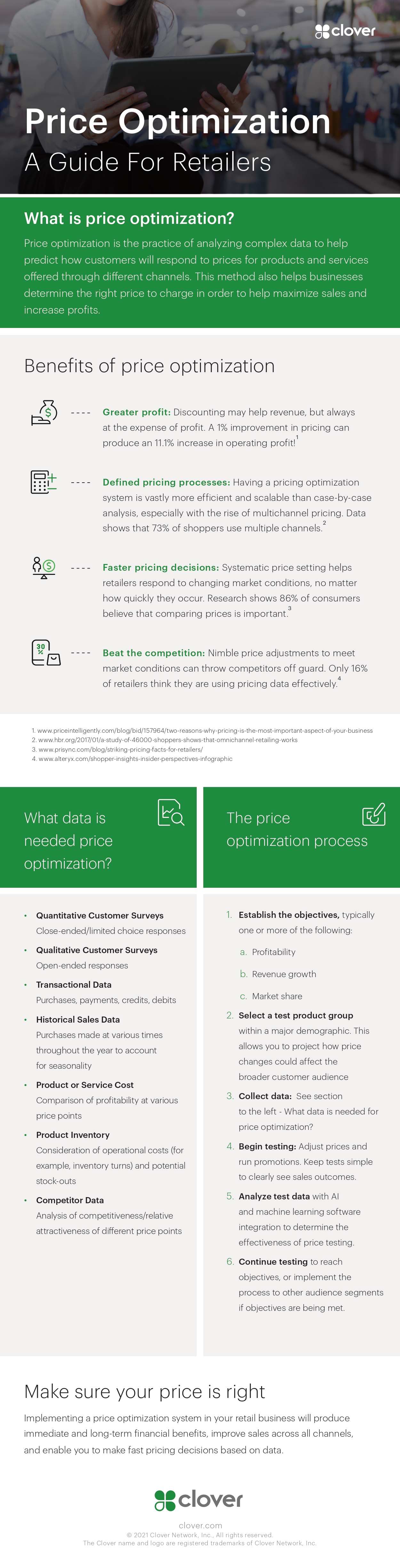

Infographic Created By Clover, Easy-to-Use POS System For Your Business